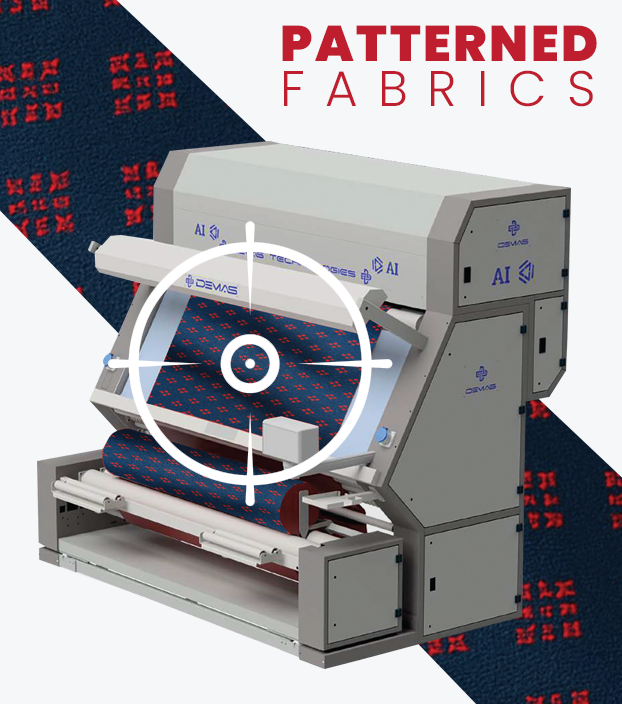

With its innovative interface, DEMAS.AI not only detects the defects during real-time streaming also simplifies the operator monitoring process. It can integrate with third-party software and generate instant reports.

Maximum Speed / Min

The live map displaying real-time error detections has simplified process management for operators. Additionally, the defects map is made available as a report.

The system displays defect images and their real-time locations in front of the operator through a user-friendly interface. Detected defects are automatically classified, recorded, and visualized on an intuitive touchscreen. A dedicated quality defect map is generated for each roll, which can be thoroughly reviewed using the integrated album software. Demas.AI offers various classification and grading options, allowing rolls to be categorized based on the number, size, and location of defects as well as specific customer criteria.